Easy.Cut Features

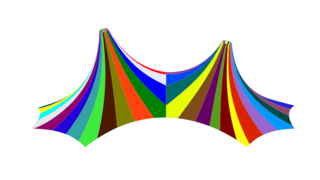

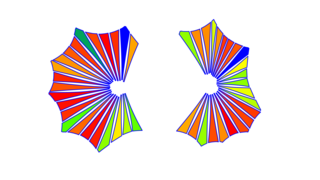

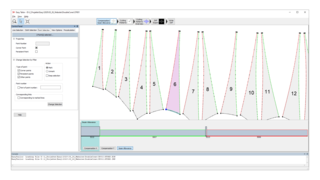

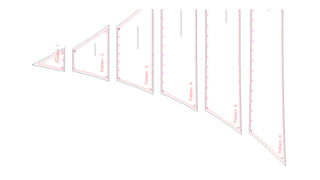

Calculation of cutting patterns in consideration of maximum pattern width (cut -off minimisation)

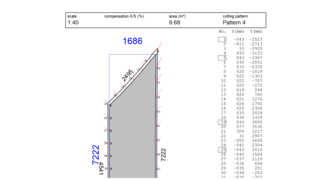

Design for manufacturability (compensation, border allowance, welding marks)

Export to cutting machines

Fully automated optimisation of pattern width in standard case

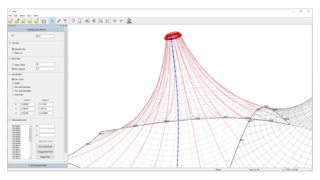

Small flattening distortion caused by the use of map projection theories

Clearly, whatever technique is used, it is necessary to introduce distortions in order to achieve the desired result. However, it is common for more distortion than necessary to be applied, and for the distortion to be badly localized. Due to the enormous variety of patterning situations, strategies which, provide the highest quality patterns, require sophisticated monitoring of distortions.

In the case of Easy.Cut automatic procedures for many cases guarantee a fast calculation with a cut-off minimisation. The design is for manufacturability: constant and non-constant compensation, border allowance and welding marks are used for both, manual and automatic cutting machines.

Back to EASY - The complete system